Stairs with stone, tile, or wooden steps on a robust concrete substructure – versatile but demanding in execution.

See how fast it worksThis category includes stairs with stone, tile, or wooden steps on a concrete substructure.

Somehow you don’t hear or read much about these stairs, although they make up a considerable share. Why is that?

Wooden or steel stairs are manufactured by specialist companies as independent components and are also advertised on the internet. Stairs with a concrete substructure, at least in residential construction in Germany, are often cast on-site together with the shell construction. If they are later covered with tiles, a stair builder was never involved in the process. And that’s where the problem lies.

Among stair experts, site-cast winder concrete stairs are considered problem stairs. Shuttering such a stair is not easy in itself. On top of that, the formwork is often not done according to specifications but according to the carpenter’s own judgment or simply “the way it’s always been done.”

This may sound harsh, but unfortunately, the fact is that many concrete stairs are improperly constructed.

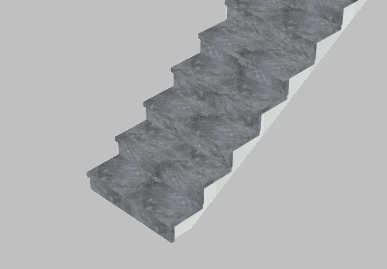

With stone steps: Particularly robust, but stone steps cannot be cut in very delicate shapes.

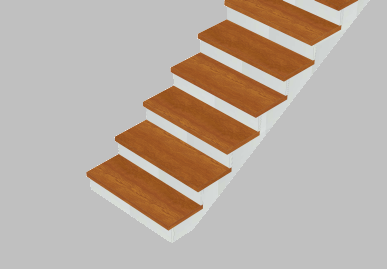

With wooden steps: Popular; instead of risers, the concrete is usually plastered and painted.

Minimalist without covering: Of course, concrete stairs can also be left completely uncovered.

For outdoor use: For example, for basement stairs, concrete stairs are the obvious choice.

As precast elements: Straight-run concrete stairs are – especially in commercial buildings – also delivered to the site as precast units.

A classic is the stair with steps and risers made of stone.

Many (myself included) find this stylish, but if shoes frequently hit the painted risers, it becomes high-maintenance.

If you’re unsure about the covering, simply leave enough “space” for wooden or stone steps. If you later decide on tiles, the difference can be compensated with screed (since tiles are thinner).