Of course, you can build stairs without software. That worked well for hundreds of years. But there are good reasons for craftsmen to stop drawing stairs 1:1 on the workshop floor. You think nobody does that anymore? Oh yes, they do!

CAD is not CAD

The magic word is CAD (Computer Aided Design), but not all CAD is the same. For craftsmen, three types of CAD software are relevant when it comes to stairs: firstly, there are general systems that basically replace the drawing board with a PC. With these you can draw anything, but the programs know nothing about stair geometry or standards. You draw line by line and must of course learn each system.

For metalworkers there are specialized steel or metal construction solutions, often as add-ons to the first systems. These programs provide automation for recurring tasks – e.g., beam connections or stairs. However, the stair modules are often geared more toward industrial stairs. Complex residential staircases cannot always be designed, and the range of variants is often limited. One advantage, though, is the direct integration of the staircase into the overall structure, such as a hall.

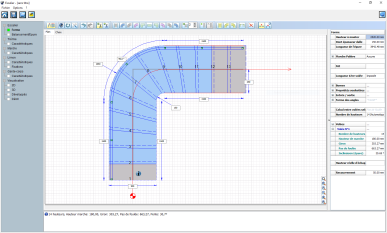

Simple data entry in the floor plan.

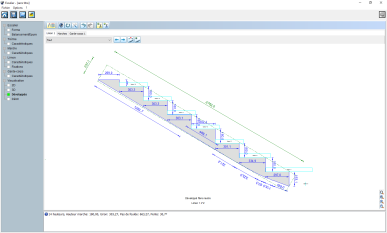

Dedicated stair construction software works differently: you simply tell the system the space you have and how the staircase should look. The software then calculates and draws automatically, so in many cases you don’t even need CAD skills. Good software provides floor plan, stringers, steps, developments, railings, and ultimately a 3D model at the push of a button. It also generates parts lists with all cutting details. Most programs create the staircase fully automatically based on your specifications, but allow manual corrections afterward. These editing options are important, since even the best software cannot replace the “gut feeling” of a stair builder.

General architectural programs also contain stair modules. These are usually designed for rough dimensions and visual representation rather than producing workshop drawings.

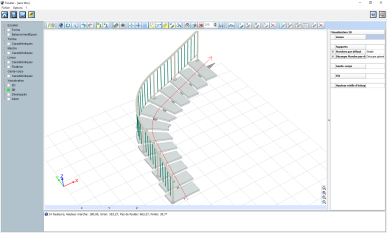

Modern stair and railing software works in 3D, even though your drawings on paper are 2D. This is the only way the software can calculate joints and other critical points accurately.

Advantages upon Advantages

So what are the benefits of specialized stair CAD? The biggest advantage is time savings in planning. Many programs can complete this in just minutes. This also makes it possible to respond to customer inquiries or present multiple variants with little effort. Time is also saved in the workshop, since complete, consistent production documents prevent misunderstandings. And if everything is done correctly, installation on site also goes quickly.

A 3D visualization provides clarity.

Even before construction, stair software offers a big advantage: the customer can be shown the staircase in photorealistic 3D without much effort – even on a laptop at the building site. Recently, this sales support has been seen as a real competitive edge.

DXF data is generated automatically.

Stair software has further advantages depending on the trade. Steel stringers, for example, can be sent as DXF files for laser cutting. Step drawings can also be sent electronically to suppliers. If a low-cost staircase is required, a laser-cut design is now the first choice and has replaced the old, labor-intensive double-stringer design. Stair software for wooden stairs can directly control woodworking machines via a post-processor. Even complex parts such as curved stringers can be produced easily, and cutting is optimized by these programs.

Good stair software also functions as an “expert system.” It checks compliance with standards and best practices. Industry-specific solutions are far superior to, for example, a general program for wooden stairs expanded with a steel module. The details quickly reveal whether the developers have real industry knowledge.

But one thing stair software cannot do: replace your expertise and experience. Even if the results are usually good, the stair builder should always cast a critical eye on the design. Good programs offer flexible post-editing options, whether for the geometry or the stringer curvature.

The Agony of Choice

So, which companies benefit from stair software? Basically, it’s a simple calculation: many users estimate the savings per staircase at several hundred euros. Of course, this depends on the design and your experience. A low-cost program under €2000 quickly pays for itself, but programs can also cost many times more. This makes specialized software worthwhile even for small businesses that don’t build only stairs. Surveys in the metalworking sector show that around 2500 metalworkers use such software and build “only” 5–20 stairs per year with it. For companies specializing in stairs, the investment is even more worthwhile.

And which program should you choose? To be clear: the selection is limited. Large stair companies often use software tailored to their production process, but for smaller businesses, only standard solutions are practical. The software should be specialized for the trade. Since smaller companies often build different stair types, the software should be versatile and not require extra modules for each design. Ease of use is important (you won’t use it every day), as is good customer support. Support should also cover stair-related questions. It’s also important that the manufacturer continuously updates the program to meet new standards. Interfaces to other CAD systems are standard today – but check compatibility carefully, especially for 3D data. A free trial version is always a good sign.

Purchasing stair CAD software should be a business decision. What prospects does stair building offer craftsmen? The industry follows the construction market. About 200,000 stairs are built annually, and more than half come from small workshops. Around one-third are in steel, wood, or stone. Renovation and replacement of old stairs with higher-quality models is increasing. This creates major opportunities for small stair manufacturers, since they can adapt to building conditions and customer wishes.

Many craftsmen feel uneasy when buying software. They are more comfortable judging a welding machine or router. That’s why it is important to research and benefit from colleagues’ experiences. Depending on complexity, training for the responsible employee is essential. In the end, this saves time, money, and frustration. Hardware requirements are usually low – a modern office PC and preferably a large monitor are enough. Buying a plotter, often more expensive than the software itself, is controversial. If you don’t need templates, you can skip it.

Conclusion: anyone building at least 5 stairs a year and looking to save time, nerves, and money should consider investing in specialized stair CAD software.

Checklist

What are the purchase costs?

What follow-up costs arise from updates or maintenance contracts?

How expensive are additional licenses?

What hardware must be purchased?

Is training required?

Is telephone support available, and if so, at what cost?

Are there experiences from colleagues?

Can the program be tested before purchase?

Does the software cover our stair types?

Are there interfaces to existing software?